Expanded Polystyrene

Expanded polystyrene (EPS) is produced from a mixture of about 90-95% polystyrene and 5-10% gaseous blowing agent, most commonly pentane. The solid plastic is expanded using steam and is injected in to an aluminum tool under high pressure. Whether white or coloured, EPS starts life the size of a grain of salt. Once the raw material has gone through the pre-expansion process the grain swells with air expanding up to 50 times its original size.

Density range

18 - 200 g/l

Trade Names:

Airpop®, Neopor®, Styropor®, RIGIPORE®®,

Key Benefits

100% Recyclable

Fully recyclable. Recycled material grades containing granulated end-of-life parts is available

Strength

Durable with high strength to weight ratio

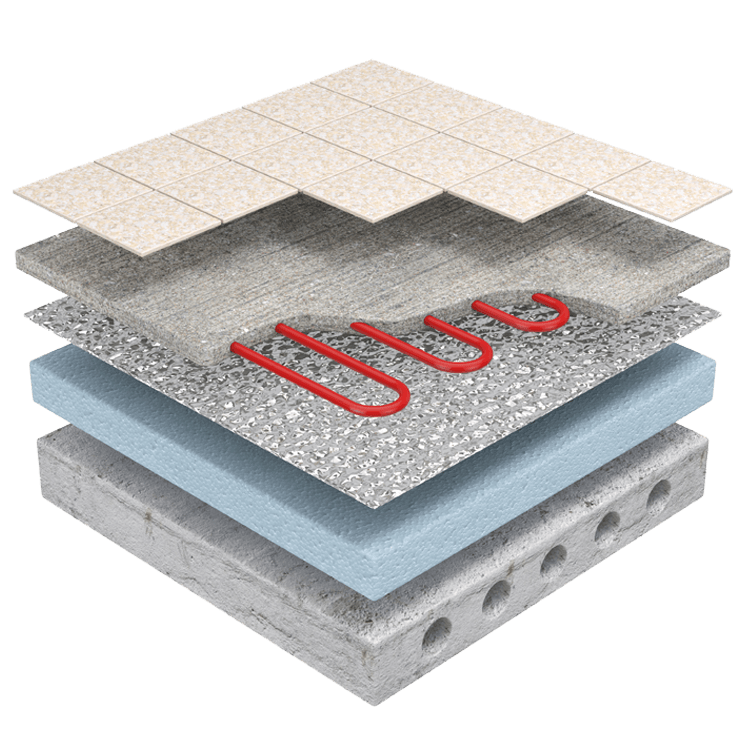

Thermal Insulation

Outstanding thermal insulation for both hot and cold applications

Resource Efficient

Raw material expands to 50 times its size producing a moulding that is 98% air. Think of a balloon - little material with lots of air

Lightweight

Generates weight saving in components leading to fuel efficiencies across many modes of transport

Colourful

Vibrant colours available for branding, improved aesthetics or colour coding purposes

Our Products

EPS Insulation

Expanded polystyrene is one of the most thermally efficient and cost-effective insulation materials to reduce...

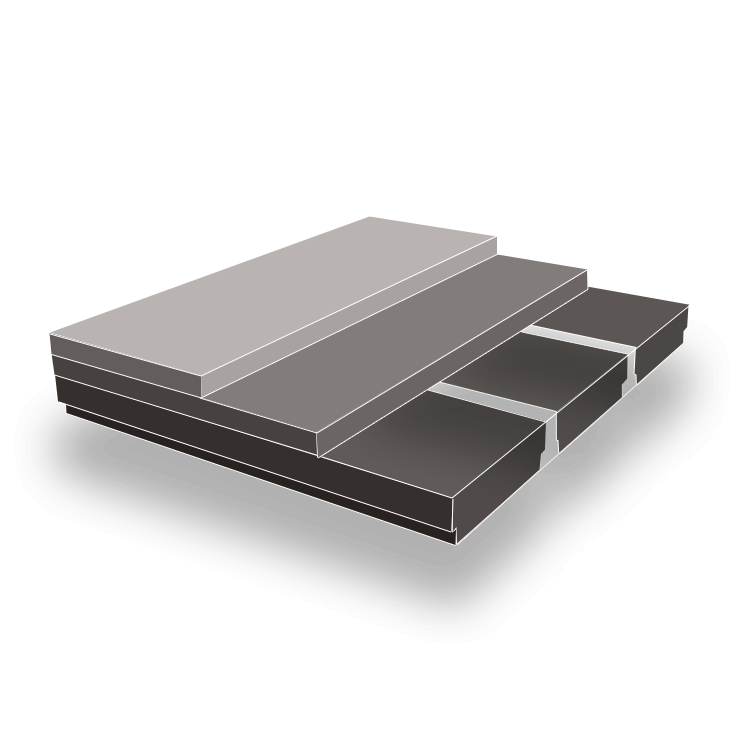

Beam and Block Infill

Beam and block infill and top sheets help improve the thermal performance of the ground...

Temperature Controlled Packaging

EPS and EPP has a low rate of thermal conductivity and is food contact safe...

Vacutainer® Trays

The logistics of shipping pharmaceutical products requires the best possible protection during transit

Add a splash of colour

Not everything is black and white, it’s pink, green, orange and blue too! We manufacture raw EPS foam that can be pre-coloured or pigments can be introduced during the expansion process without any adverse effects on the performance or properties of the moulded product.

Consider injecting EPP and EPS parts with some colour for branding, product identification or to simply improve the final aesthetic and visual appeal.

How can we help you?

Contact us

Ready to discover your sustainable solution?